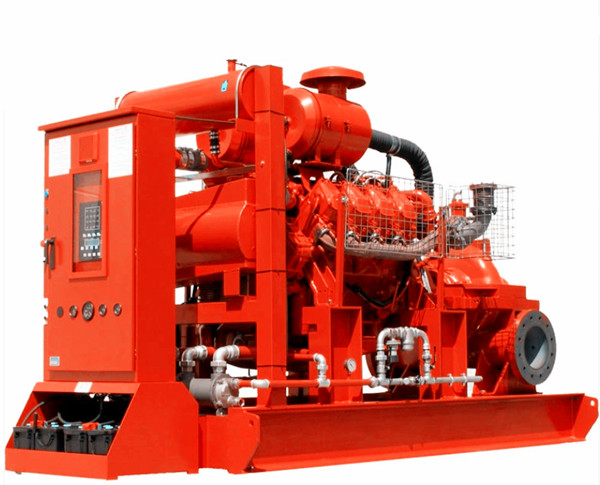

fire protection and emergency diesel engine pump

General function

1) A verticle control panel that uses PLC DC programmable controller as the core of master control, could mannualy or automatically control the water pump’s diesel engine unit via cables.

2) The diesel engine is equipped with sensor for detecting velocity, temperature of water and oil, and oil pressure, used for inspection over the operational parameter of diesel engines and warning the signal source of protection.

3) The control panel has diesel engine hour totalizer, and indicates water and oil temperature, oil pressure, velocity, current (charge), and warning of high/low temperature of water and oil, overspeed, and failure to start for three times. Besides, it installs DC24V electrical source, indicator lights of pre-lubricant, pre-heating, charge (civil power charge),diesel engine start, engine unit operational and shutdown, etc., and electrical source key switch, and button/switch mannually or automatically controlled; it also could set button/switch of municiple warning, silencing and reset.

Function of control

1) Self-starting function

When the mannual/auto switch on the control panel is on auto mode, mannual operation would not work. Once the control panel received start order, it would proceed self-starting programme. Before the first start, pre-lubricant pump start working for 10-20 seconds, then start diesel engine (for about 5-8 seconds); if the start fail, wait for 5-10 seconds beofre re-start; repeat the trial for 3 times; if it ends in failure after trial start for three times, output the signal of start failure. Once it starts sucessfully, idle running for 5-10 seconds then automatically rise to the specified velocity, meanwhile send signal and switch on the clutch within 20 seconds to start for normal operation.

2) Auto pre-heating function

The engine unit could add pre-heating system device in order to ensure a perfect start of the diesel engine when the environmental temperature in the engine room lower than 5 centigrade

3) Pre-lubricating system

When start a high power multi-cylinder diesel engine with low ambient temperature, a bigger start resistance will occur, therefore, a pre-lubricating pump should be added to impose an pre-lubricating before start running the diesel engine.

4) Auto-charging function

For the purpose of a perfect start to diesel engine even in case of an interruption of AC power supply, we can set auto-charging device in the control cabinet which through AC220C civil power to charge the storage battery, besides charing by power generator to charging generator when diesel engine is running.

5) Auto-stop function

When the auto control panel receives a warning stop signal, the central control room stop signal or emergency stop signal, the engine unit will proceed shutdown procedure.

6) Manual start function

Before formally running the machine, manually push each button to inspect each function such as pre-lubricating, start, speed-raising, speed reduction, shutdown and clutch of switching on/off power; when everything is running on track, the automatic procedure could proceed.

7) Protective warning function

When the water or oil temperature overheat (above 0.17mpu), or malfunction occurs such as overspeed, and disconnection of velocity sensor, the control cabinet would give warning signals.

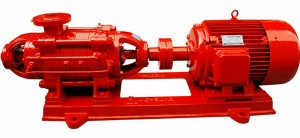

Select water pump

| Pump Water configuration | Specification | Single engine multi-stage | Suggested model | |

|---|---|---|---|---|

| ① | Large volume | Q=540m3/n below | multi-stage | D Model |

| ① | Big lift | H=697m below | multi-stage | D Model |

| ① | Super power | 1120Km below | multi-stage | D Model |

| ② | Small volume | Q=460mVn below | Single-stage | IS Model |

| ② | Small lift | H=145m below | Single-stage | IS Model |

| ② | Low power | N=llOKm below | Single-stage | IS Model |

| ③ | Super volume | Q=6460m3/n below | Single-stage | SH、 0S Model |

| ③ | Small lift | H=140m below | Single-stage | SH、 0S Model |

| ③ | High power | N=960Km below | Single-stage | SH、 0S Model |

| ④ | Small volume | Q=45m3/n below | Multi-stage | DC、 DG Model |

| ④ | Big lift | H=301m below | Multi-stage | DC、 DG Model |

| ④ | Low power | N=75Km below | Multi-stage | DC、 DG Model |

| ⑤ | Mediate volume | Q=288m3/n below | Multi-stage | DAi Model |

| ⑤ | Mediate lift | H=333m below | Multi-stage | DAi Model |

| ⑤ | Mediate power | N=200Km below | Multi-stage | DAi Model |