D, DM, DF, DY series multistage centrifugal pump

D/DF/DY/MD Horizontal multi-stage pump description

The series of pumps single horizontal multi-stage centrifugal pump, using the country recommended the use of efficient energy-saving products, hydraulic model, with high efficiency, wide range of performance, safe and stable operation, low noise, long life, easy installation and maintenance Etc.

Products for the delivery of solid particles (abrasive), without suspended solids of water or physical and chemical properties similar to the other liquid water use. It can also be used to convey hot water, oil, corrosive or abrasive-containing media by changing the material of the pump (or the material of the pump flow component), the sealed form and the increased cooling system.

Pump inlet allowable pressure less than 0.6MPa.

Model:

The first letter indicates:

D-single suction multistage segmental centrifugal fresh water pump

DM-single suction multistage segmental centrifugal wear pump

DF-single suction multistage segmental anti-corrosive pump

DY-single suction multistage segmental centrifugal oil pump

The second number indicates the capacity at the designed point. (m3/h)

The third number indicates the single stage head at the designed point. (m)

The fourth number indicates the number of stage.

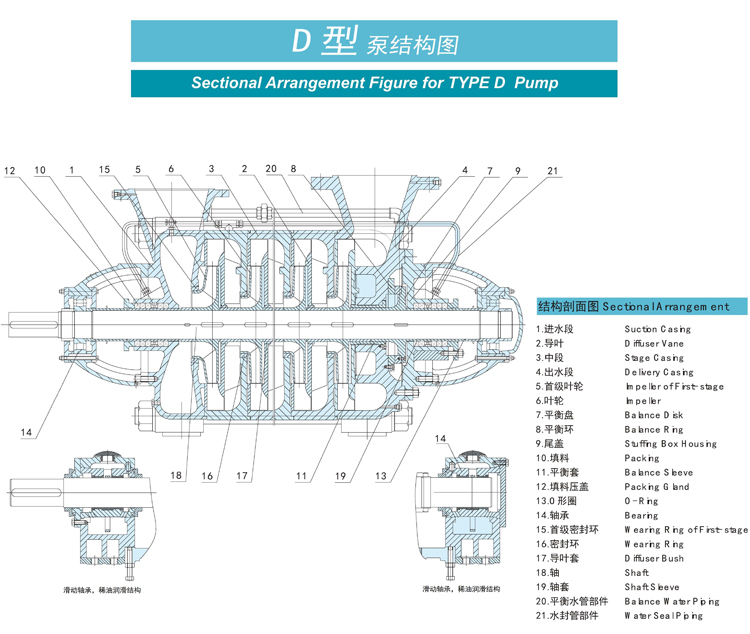

D/DF/DY/MD Horizontal multi-stage pump structural features

D, DF, DY, MD-type pump horizontal, single-suction, multi-stage multi-stage centrifugal pump, suction port for the horizontal direction, the vertical exit for the outlet. Pump part of the water, the middle, the water section of the pump part of the pump through the tightening bolts connected into one, and according to the pump head to select the pump series.

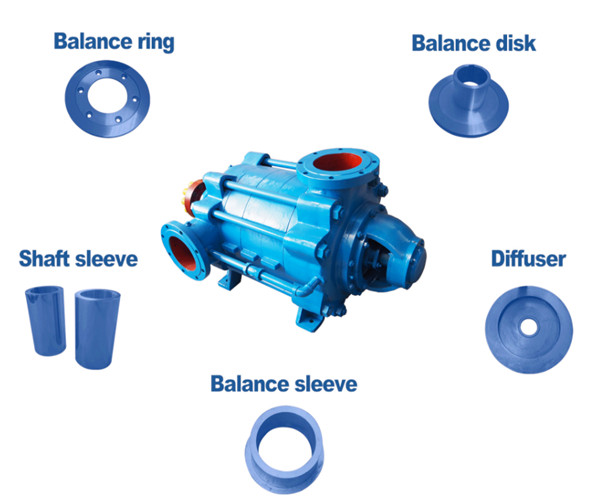

The series of pump rotor part of the main by the installation and the shaft of the impeller, sleeve, balance plate and other components, including the number of impellers according to the pump series. The shaft parts are fastened with a flat key and a shaft nut to fit the shaft. The entire rotor is supported by both ends of the rolling bearing or sliding bearing. Bearings according to different models, do not bear the axial force, the axial force balance by the balance plate.

The sealing surface between the inlet section, the middle section and the effluent section of the pump is sealed with a sealant or an O-ring. The sealing ring and the guide vane cover are sealed between the rotor part and the fixed part. When the sealing ring and guide vane The degree of wear of the sleeve has affected the performance of the pump and should be replaced.

Shaft seal in the form of mechanical seal and packing seal two. When the pump is sealed with the packing, the position of the packing ring is placed correctly, and the tightness of the packing must be appropriate. It is advisable for the liquid to drop one by one. Pump of various sealing elements installed in the sealed cavity, the cavity to pass a certain pressure of water, water seal, water or water lubrication role. A replaceable sleeve is provided at the shaft seal to protect the pump shaft.

(D85-67, D155-67 type pump can be used for sliding bearings, thin oil lubrication structure, can also be used to roll bearings, the use of rolling bearings, , Dry oil lubrication structure).

The series of pumps through the elastic coupling directly driven by the prime mover, from the direction of the prime mover, the pump clockwise rotation.

(If the user has special requirements for the material and structure of the pump, it can be negotiated with the stupid company, the company can change the direction of the pump import and export according to the user 's demand, and realize the multi - export structure and function of the series.

D/DF/DY/MD Horizontal multi-stage pump over flow parts material

D type: over flow parts for the cast iron, shaft for the 45 # steel;

DF type: over-current components according to the requirements of divided into cast steel and stainless steel, according to the transmission medium temperature and corrosive material;

DY type: over-current components according to the requirements of the cast iron, cast steel and cast stainless steel, according to the transmission medium temperature material;

MD type: over-current parts for the wear-resistant cast iron or cast iron cast iron.

D/DF/DY/MD Horizontal multi-stage pump model meaning

Such as D (DF, DY, MD) 600-60 × 6

D ---- that multi-level water centrifugal pump

DF ---- that decay multi-stage centrifugal pump

DY ---- that multi-stage centrifugal oil pump

MD ---- said wear-resistant multi-stage centrifugal pump

600 ---- that the design point of traffic is 600m3 / h

60 ---- that the design point of single-stage head for the 60m

6 ---- that the level of 6

Such as 150D30 x 7

150 ---- that the pump inlet diameter of 150mm

D ---- that multi-stage centrifugal clean water pump

30 ---- that the pump design point single-stage head is 30m

7 ---- that the level of 7

Structure:

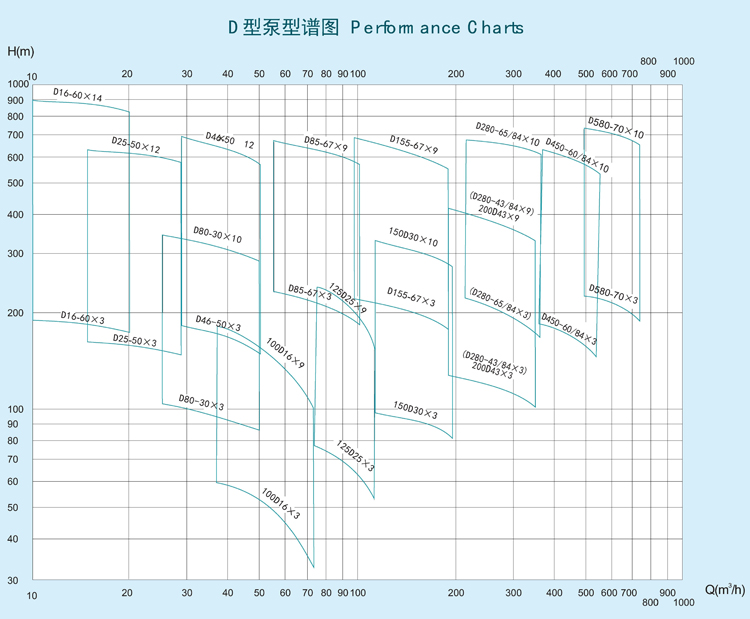

Performance Chart:

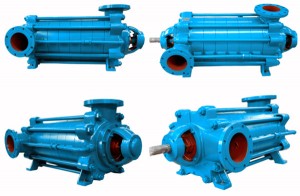

Pump Performance Table