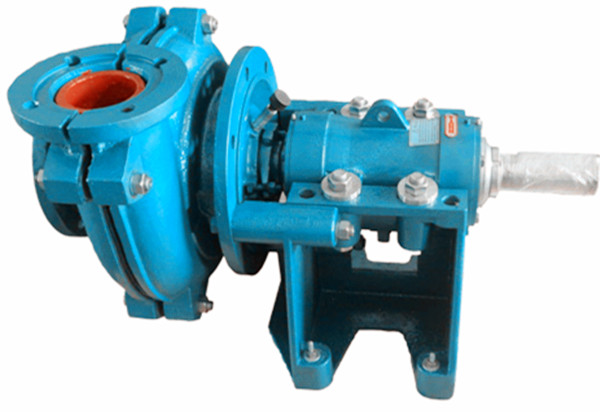

TZSA series Compact Slurry Pump

Application and Features:

Type TZSA pumps are cantilevered, horizontal, centrifugal slurry pumps.They are suitable for delivering low abrasive, low density slurries for metallurgical, mining, coal and build material departments.The shaft seal is adopted both gland seal and centrifugal seal.

Type TZSA pumps are adopted high speed operating and so they have small volumes saving floor area.The frame plates have changeable, wear-resistant, metal liners or rubber liners and the impellers are made of wear-resistant metal or rubber (Rubber for frame plates, impellers of pumps with discharge dia. above 550mm.) The discharge position by request may be rotated 8 different angles at internal of 45 degrees for installation and application.

Wetted Parts

Liners – wide variety of metallurgic and elastomeric options (metal and elastomer interchangeable) – active engineered attachment mechanism to casing via threaded bolts as opposed to unreliable glue

Impeller – higher efficiency rates (up to 90+ %) – pump out vanes on rear and front (on closed impellers) reduce recirculation within pump, and aid in preventing seal contamination

Throat bush – wide variety of metallurgic and elastomeric options (metal and elastomer interchangeable) – adjustable via cotters to account for wear over time and increase efficiency

Shaft seal

Expeller Seal(Centrifugal Seal) – Available with low flow water flush or zero flow (grease lubricated) options to provide exceptional sealing where water introduction to the seal is intolerable or limited.

Stuffing Box – Gland sealing with packing and lantern ring.

Bearing assembly - All bearings assembled with highest quality tapered roller bearings in controlled environments to prevent lubricant and housing contamination – oversized shaft diameters and reduced overhang in the wet end contribute to long life and reliability in the field

Pump Casing – Split-case design allows for ease of access and maintenance on wet end parts – cast ductile iron with exterior ribbing provides increased pressure ratings and reliable service over time

Frame Base – A very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

Structure Drawing:

Selection Chart:

Performance Table:

|

Type |

Capacity Q(m3/h) |

Head H(m) |

Speed (r/min) |

Max. eff.(%) |

NPSHr(m) |

|

20TZSA-PA |

2.34-10.8 |

6-37 |

1400-3000 |

33 |

2-4 |

|

50TZSA-PB |

16.2-76 |

9-44 |

1400-2800 |

56 |

2.5-5.5 |

|

75TZSA-PC |

18-151 |

4-45 |

900-2400 |

57 |

2-5 |

|

100TZSA-PD |

50-252 |

7-46 |

800-1800 |

61 |

2-5 |

|

150TZSA-PE |

115-486 |

12-51.5 |

800-1500 |

66 |

2-6 |

|

200TZSA-PE |

234-910 |

9.5-40 |

600-1100 |

74 |

3-6 |

|

250TZSA-PE |

396-1425 |

8-30 |

500-800 |

75 |

2-10 |

|

300TZSA-PS |

468-2538 |

8-55 |

400-950 |

77 |

2-10 |

|

350TZSA-PS |

650-2800 |

10-53 |

400-840 |

79 |

3-10 |

|

400TZSA-PST |

720-3312 |

7-51 |

300-700 |

81 |

2-10 |

|

450TZSA-PST |

1008-4356 |

9-42 |

300-600 |

81 |

2-9 |

|

550TZSA-PTU |

1980-7920 |

10-54 |

250-475 |

84 |

4-10 |

|

650TZSA-PU |

2520-12000 |

10-59 |

200-425 |

86 |

2-8 |

|

750TZSA-PUV |

2800-16000 |

6-52 |

150-365 |

86 |

2-8 |