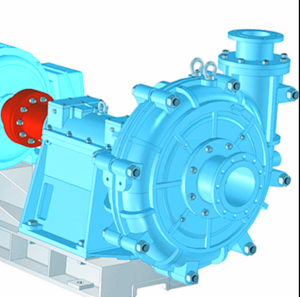

Type UHB-ZK Corrosion Resistant Mortar Mud Pump

UHB-ZK corrosion resistant wear-resistant plastic mortar pump Overview:

UHB-ZK series of anti-corrosion wear-resistant mortar pump is a variety of conditions to adapt to the conditions of the pump, such as conveying acid, alkaline solution or slurry, corrosive pulp, sewage and so on. The pump is resistant to corrosion and wear, the use of a wide range.

Strong wear resistance: all parts of the flow through the use of ultra-high molecular weight polyethylene (UHMW-PE) manufacturing, ultra-high molecular weight polyethylene (UHMW-PE) wear resistance of the first plastic, nylon 66 (PA66) , Polytetrafluoroethylene (PTFE) 4 times higher, is carbon steel, stainless steel wear resistance of 7-10 times. Strong impact resistance: ultra-high molecular weight polyethylene impact strength is (acrylonitrile / butadiene / styrene) copolymer (ABS) 5 times.

Excellent corrosion resistance: the pump in a certain temperature and concentration range of various corrosive media (acid, alkali, salt) and organic solvents, safe and reliable, non-toxin decomposition: the pump used in high molecular weight polyethylene (UHMW -PE) is extremely stable in chemical properties and is therefore suitable for use in the food industry.

Resistant to wear, a pump multi-purpose, acid-base liquid slurry are applicable. The pump is made of steel-lined ultra-high molecular weight polyethylene structure with a lining thickness of 8 ~ 20mm.

UHB-ZK corrosion resistant wear-resistant plastic mortar pump Design Features:

The seal is composed of an impeller (or vice impeller) and a parking seal (rubber seal). During operation, the centrifugal force generated by the rotation of the secondary impeller (or the secondary blade) causes the inside of the sealed chamber to be in a negative pressure state, thereby preventing the liquid from leaking outwards. At this time, the parking seal does not work and the lip of the rubber oil seal is released by the negative pressure , And the sleeve to produce a certain gap, to reduce the wear between them to extend the service life, shutdown, due to the secondary impeller (or vice leaves) to stop the rotation, the sealed cavity from negative pressure into positive pressure, parking seal began to work, Rubber seal lip under the pressure of tightly wrapped around the sleeve, so as to achieve the purpose of sealing, if allowed to seal the liquid into the medium, you can choose K1-type power seal, you can add external cooling water device to extend the service life of oil seal. The sealed oil seal is made of rubber, mainly used for conveying solid particles containing slurry, containing impurities such as sewage and other corrosive.

The seal is WB2 mechanical seal, is a special multi-spring PTFE corrugated pipe fittings mechanical seal, without adding cooling water. The sealing ring is made of engineering ceramics and filled with tetrafluoroethane. It has the advantages of simple structure, convenient installation and good interchangeability. It is mainly used for conveying corrosive media without hard particles and no solidification. Can also be replaced according to user requirements 169 mechanical seal, for conveying crystalline alkali, salt solution and other chemical media. If the dynamic and static ring are made of engineering ceramics, can be transported with hard particles containing corrosive media.

This product is widely used in chemical industry, acid, alkali, smelting, rare earth, pesticide, dyes, medicine, paper, electroplating, electrolysis, pickling, radio, foil, scientific research institutions, defense industry and other industries to deliver any concentration of acid , Alkaline, oil, rare precious liquid, toxic liquid, volatile chemical medium. Especially easy to leak, flammable, explosive liquid delivery.

Applicable medium: 80% concentration of sulfuric acid, 50% of the following nitric acid, a variety of concentrations of hydrochloric acid, liquid caustic soda, both for the liquid is also suitable for slurry. Sulfuric acid phosphate fertilizer industry: dilute acid, mother liquor, sewage, sea water, fluorosilicic acid, phosphoric acid slurry and other media delivery. Non-ferrous metal smelting industry: especially for lead, zinc, gold, silver, copper, manganese, cobalt, rare earth and other wet smelting of various acid, corrosive pulp, slurry (filter with machine) Such as medium delivery.

Use temperature: -20 ℃ ~ 95 ℃ Material improvement up to: 120 ℃

Note: Do not allow air to run.

UHB-ZK corrosion resistant wear-resistant plastic mortar pump Performance parameter table:

| No |

Model |

Speed(Rev) =2900r/min Medium density=1000kg/m ³ |

|||||||

|

Flow |

Pump head |

η |

Inlet |

Outlet |

Npsh |

Power |

Weight |

||

|

(m³/h) |

(m) |

(%) |

(mm) |

(mm) |

(m) |

(kw) |

(kg) |

||

|

1 |

UHB-ZK32-25-125 |

3.6 |

20 |

18 |

Ф32 |

Ф25 |

3 |

1.5 |

95 |

|

2 |

UHB-ZK32-25-160 |

3.6 |

32 |

13 |

Ф32 |

Ф25 |

3 |

2.2 |

105 |

|

3 |

UHB-ZK40-32-125 |

6.3 |

20 |

21 |

Ф40 |

Ф32 |

3 |

2.2 |

110 |

|

4 |

UHB-ZK40-32-160 |

6.3 |

32 |

25 |

Ф40 |

Ф32 |

3 |

3 |

110 |

|

5 |

UHB-ZK50-32-125 |

12.5 |

20 |

42 |

Ф50 |

Ф32 |

3 |

3 |

110 |

|

6 |

UHB-ZK50-32-160 |

12.5 |

32 |

40 |

Ф50 |

Ф32 |

3 |

4 |

120 |

|

7 |

UHB-ZK50-40-200 |

12.5 |

50 |

30 |

Ф50 |

Ф40 |

5 |

7.5 |

170 |

|

8 |

UHB-ZK65-50-125 |

25 |

20 |

53 |

Ф65 |

Ф50 |

3.5 |

4 |

130 |

|

9 |

UHB-ZK65-50-160 |

25 |

32 |

51 |

Ф65 |

Ф50 |

3.5 |

7.5 |

145 |

|

10 |

UHB-ZK65-50-200 |

25 |

50 |

46 |

Ф65 |

Ф50 |

3.5 |

11 |

210 |

|

11 |

UHB-ZK65-50-250 |

25 |

80 |

30 |

Ф65 |

Ф50 |

3.5 |

22 |

250 |

|

12 |

UHB-ZK80-65-125 |

50 |

20 |

56 |

Ф80 |

Ф65 |

4 |

7.5 |

150 |

|

13 |

UHB-ZK80-65-160 |

50 |

32 |

55 |

Ф80 |

Ф65 |

4 |

11 |

180 |

|

14 |

UHB-ZK80-65-200 |

50 |

50 |

49 |

Ф80 |

Ф65 |

4 |

18.5 |

265 |

|

15 |

UHB-ZK80-65-250 |

50 |

80 |

49 |

Ф80 |

Ф65 |

4 |

30 |

450 |

|

16 |

UHB-ZK100-80-125 |

100 |

20 |

57 |

Ф100 |

Ф80 |

4.5 |

15 |

240 |

|

17 |

UHB-ZK100-80-160 |

100 |

32 |

60 |

Ф100 |

Ф80 |

4.5 |

18.5 |

290 |

|

18 |

UHB-ZK100-80-200 |

100 |

50 |

56 |

Ф100 |

Ф80 |

5 |

30 |

440 |

|

19 |

UHB-ZK125-100-125 |

150 |

20 |

60 |

Ф125 |

Ф100 |

5.5 |

18.5 |

480 |

|

20 |

UHB-ZK125-100-160 |

150 |

32 |

58 |

Ф125 |

Ф100 |

5.5 |

30 |

520 |

|

21 |

UHB-ZK125-100-200 |

150 |

40 |

55 |

Ф125 |

Ф100 |

5.5 |

37 |

530 |

|

No |

Model |

Speed(Rev) =1450r/min Medium density=1000kg/m³ |

|||||||

|

Flow |

Pump head |

η |

Inlet |

Outlet |

Npsh |

Power |

Weight |

||

|

(m³/h) |

(m) |

(%) |

(mm) |

(mm) |

(m) |

(kw) |

(kg) |

||

|

1 |

UHB-ZK50-32-125 |

6.3 |

5 |

37 |

Ф50 |

Ф32 |

3 |

0.75 |

80 |

|

2 |

UHB-ZK50-32-160 |

6.3 |

8 |

35 |

Ф50 |

Ф32 |

3 |

0.75 |

80 |

|

3 |

UHB-ZK50-40-200 |

6.3 |

12.5 |

35 |

Ф50 |

Ф40 |

5 |

1.5 |

115 |

|

4 |

UHB-ZK65-50-125 |

12.5 |

5 |

45 |

Ф65 |

Ф50 |

3.5 |

1.1 |

110 |

|

5 |

UHB-ZK65-50-160 |

12.5 |

8 |

43 |

Ф65 |

Ф50 |

3.5 |

1.1 |

115 |

|

6 |

UHB-ZK65-50-200 |

12.5 |

12.5 |

39 |

Ф65 |

Ф50 |

3.5 |

2.2 |

160 |

|

7 |

UHB-ZK65-50-250 |

12.5 |

20 |

37 |

Ф65 |

Ф50 |

3.5 |

4 |

240 |

|

8 |

UHB-ZK65-50-315 |

12.5 |

32 |

39 |

Ф65 |

Ф50 |

3.5 |

7.5 |

270 |

|

9 |

UHB-ZK80-65-125 |

25 |

5 |

48 |

Ф80 |

Ф65 |

4 |

1.5 |

130 |

|

10 |

UHB-ZK80-65-160 |

25 |

8 |

53 |

Ф80 |

Ф65 |

4 |

1.5 |

135 |

|

11 |

UHB-ZK80-65-200 |

25 |

12.5 |

45 |

Ф80 |

Ф65 |

4 |

3 |

170 |

|

12 |

UHB-ZK80-65-250 |

25 |

20 |

42 |

Ф80 |

Ф65 |

4.5 |

5.5 |

270 |

|

13 |

UHB-ZK80-50-315 |

30 |

32 |

39 |

Ф80 |

Ф50 |

5 |

7.5 |

295 |

|

14 |

UHB-ZK80-65-315 |

25 |

32 |

39 |

Ф80 |

Ф65 |

5 |

11 |

295 |

|

15 |

UHB-ZK80-65-400 |

25 |

50 |

35 |

Ф80 |

Ф65 |

5 |

22 |

480 |

|

16 |

UHB-ZK100-80-125 |

50 |

5 |

52 |

Ф100 |

Ф80 |

5 |

1.5 |

165 |

|

17 |

UHB-ZK100-80-160 |

50 |

8 |

55 |

Ф100 |

Ф80 |

5 |

2.2 |

220 |

|

18 |

UHB-ZK100-80-200 |

50 |

12.5 |

52 |

Ф100 |

Ф80 |

5 |

4 |

340 |

|

19 |

UHB-ZK100-80-250 |

50 |

20 |

50 |

Ф100 |

Ф80 |

5 |

7.5 |

390 |

|

20 |

UHB-ZK100-80-315 |

50 |

32 |

46 |

Ф100 |

Ф80 |

5 |

15 |

450 |

|

21 |

UHB-ZK100-80-400 |

50 |

50 |

42 |

Ф100 |

Ф80 |

5 |

22 |

520 |

|

22 |

UHB-ZK125-100-160 |

100 |

8 |

56 |

Ф125 |

Ф100 |

5 |

11 |

480 |

|

23 |

UHB-ZK125-100-200 |

100 |

12.5 |

54 |

Ф125 |

Ф100 |

5 |

15 |

500 |

|

24 |

UHB-ZK125-100-250 |

100 |

20 |

52 |

Ф125 |

Ф100 |

5 |

18.5 |

550 |

|

25 |

UHB-ZK125-100-315 |

100 |

32 |

49 |

Ф125 |

Ф100 |

5.5 |

30 |

680 |

|

26 |

UHB-ZK125-100-400 |

100 |

50 |

46 |

Ф125 |

Ф100 |

5.5 |

37 |

720 |

|

27 |

UHB-ZK150-125-200 |

200 |

12.5 |

56 |

Ф150 |

Ф125 |

5.5 |

22 |

720 |

|

28 |

UHB-ZK150-125-250 |

200 |

20 |

53 |

Ф150 |

Ф125 |

5.5 |

30 |

780 |

|

29 |

UHB-ZK150-125-315 |

200 |

32 |

48 |

Ф150 |

Ф125 |

6 |

45 |

850 |

|

30 |

UHB-ZK150-125-400 |

200 |

50 |

43 |

Ф150 |

Ф125 |

6 |

75 |

1100 |

|

31 |

UHB-ZK200-150-250 |

400 |

20 |

56 |

Ф200 |

Ф150 |

7 |

55 |

890 |

|

32 |

UHB-ZK200-150-315 |

400 |

32 |

59 |

Ф200 |

Ф150 |

7 |

75 |

1120 |

|

33 |

UHB-ZK200-150-400 |

400 |

50 |

62 |

Ф200 |

Ф150 |

7 |

110 |

1480 |

|

34 |

UHB-ZK250-200-250 |

650 |

20 |

68 |

Ф200 |

Ф150 |

7.5 |

75 |

1150 |

|

35 |

UHB-ZK250-200-315 |

650 |

32 |

66 |

Ф200 |

Ф150 |

7.5 |

110 |

1620 |

|

36 |

UHB-ZK250-200-400 |

650 |

50 |

65 |

Ф200 |

Ф150 |

7.5 |

132 |

1880 |

|

37 |

UHB-ZK300-250-315 |

1000 |

32 |

70 |

Ф300 |

Ф250 |

8 |

160 |

2150 |

|

38 |

UHB-ZK300-250-400 |

1000 |

50 |

66 |

Ф300 |

Ф250 |

8 |

250 |

2800 |