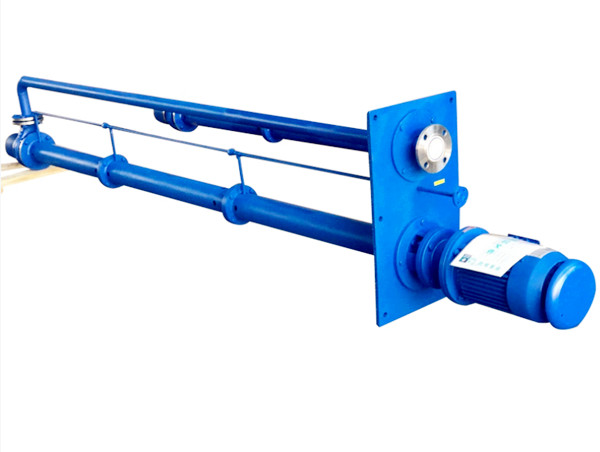

FYH long shaft chemical vertical submersible pump

1 Summarize:

FYH Submerged chemical pump is single suction chemical centrifugal pump, part of the pump is immersion in liquid. It can be activated without irrigation pumps or vacuum, and it is easy to use. Submerged chemical pumps are designed and improved by the our company, based on the traditional anti-corrosion liquid and the Swiss Sulzer company’s advanced technique about similar products; They choose the unique structure of the impeller, and canceled other ordinary liquid pump’s mechanical seals. Based on the medium particle size and of different characteristics, the impeller can be used closed or open type; enable the pump has merits of energy efficient, no leakage, and long life.

2 Usage:

Widely used in petroleum, chemical, metallurgy, synthetic fiber, medicine, food, etc it can be used for transporting sewage treatment department and suspended particles of the corrosive liquid.

3 Characteristics:

The vertical submerged pump has beautiful appearance, directly installed on the medium transmission storage, no additional area, thereby reducing the infrastructure investment. The cancelling of the mechanical seal has solved other liquid pump mechanical seal’s problem of easy to be fray, regularity repair. It saves the pump run cost and advance the work efficiency. The temperature: -20℃~+180℃. ...Liquid under the insert length: 0.5~4m.flux: 6.3 ~ 400m3/h outlet pressure: 5- 80m,rotate speed 1450-2900r/min

4 Technical Data:

FYH Submerged chemical pump(High Speed)

| Model | Outlet Diameter | Capacity | Head | Speed | Power | |

| mm | m3/h | L/S | m | r/min | kw | |

| 40FYH-160 | 32 | 6.3 | 1.75 | 32 | 2900 | 2.2 |

| 40FYH-160A | 32 | 5.9 | 1.64 | 28 | 2900 | 1.5 |

| 40FYH-200 | 32 | 6.3 | 1.75 | 50 | 2900 | 4 |

| 40FYH-200A | 32 | 5.9 | 1.64 | 44 | 2900 | 3 |

| 50FYH-125 | 40 | 12.5 | 3.47 | 20 | 2900 | 2.2 |

| 50FYH-125A | 40 | 11 | 3.05 | 16 | 2900 | 1.5 |

| 50FYH-160 | 40 | 12.5 | 3.47 | 32 | 2900 | 3 |

| 50FYH-160A | 40 | 11 | 3.05 | 28 | 2900 | 2.2 |

| 50FYH-200 | 40 | 12.5 | 3.47 | 50 | 2900 | 5.5 |

| 50FYH-200A | 40 | 11 | 3.05 | 44 | 2900 | 4 |

| 65FYH-125 | 50 | 25 | 6.94 | 20 | 2900 | 3 |

| 65FYH-125A | 50 | 22.3 | 6.19 | 16 | 2900 | 2.2 |

| 65FYH-160 | 50 | 25 | 6.94 | 32 | 2900 | 5.5 |

| 65FYH-160A | 50 | 22.3 | 6.19 | 28 | 2900 | 4 |

| 65FYH-200 | 50 | 25 | 6.94 | 50 | 2900 | 11 |

| 65FYH-200A | 50 | 22.3 | 6.19 | 44 | 2900 | 7.5 |

| 65FYH-250 | 50 | 25 | 6.94 | 80 | 2900 | 15 |

| 65FYH-250A | 50 | 22.3 | 6.19 | 70 | 2900 | 11 |

| 80FYH-125 | 65 | 50 | 13.9 | 20 | 2900 | 5.5 |

| 80FYH-125A | 65 | 45 | 12.5 | 16 | 2900 | 4 |

| 80FYH-160 | 65 | 50 | 13.9 | 32 | 2900 | 7.5 |

| 80FYH-160A | 65 | 45 | 12.5 | 28 | 2900 | 5.5 |

| 80FYH-200 | 65 | 50 | 13.9 | 50 | 2900 | 15 |

| 80FYH-200A | 65 | 45 | 12.5 | 44 | 2900 | 11 |

| 80FYH-250 | 65 | 50 | 13.9 | 80 | 2900 | 22 |

| 80FYH-250A | 65 | 45 | 12.5 | 70 | 2900 | 18.5 |

| 100FYH-160 | 80 | 100 | 27.8 | 32 | ||

Washing method

Introduce the clean liquid washing plain bearing to guarantee the pump rotate safety. Two methods can be selected to the different medium.

*Self-washing

When the medium conveyed by the pump is clean, adopt this method to carry out the washing. Lead a pipeline from the pump outlet flange,

make the washing liquid flow to various plain bearings, lubricate the plain bearing, bring the heat produced by friction and play a temperature dropping function.

*Out-washing

When the medium conveyed by the pump contains the small grain, adopt this method to carry out the washing, connect a pipeline from the exterior,

lead the clean washing liquid to wash the various plain bearing, lubricate the plain bearing, bring the heat produced by friction set, play a temperature

dropping function, meanwhile, advoid the solid grain entering the friction set.