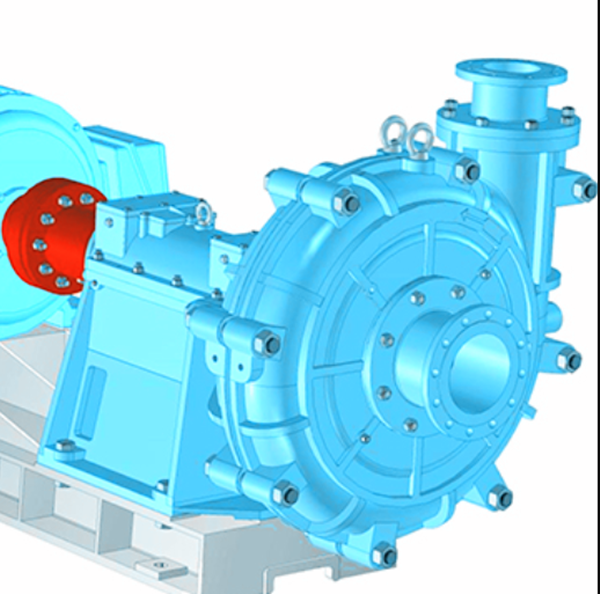

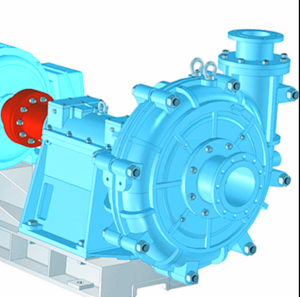

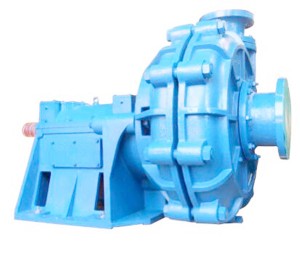

Type ZGB(P) Slurry Pump

Function Introduction:

1. advanced hydraulic performance, CAD modern design , high efficiency and lower abrasion rate 2. wide passage, non-clogging and good performance of NPSH .3. expeller seal combined with packing seal and mechanical seal have be adopted to guarantee the slurry from leakage.4. the reliability design ensures long MTBF(mean time between events)5. the metric bearing with oil lubrication, reasonable lubricating and cooling systems ensure the bearing to be operated under the lower temperature.

6.the materials of wet parts had the good performance of anti-wearing and anti-corrosion, the pump can be used for seawater ash-removing to prevent it from the corrosion of sweater, salt and mist ,and electrochemical corrosion.

7.the pump can be operated in series with multi-stage within permissible pressure . the permissible maximum working pressure is 3.6 Mpa .

The series of pump has the advantage of reasonable construction , high efficiency, reliable operation and easy maintenance. It can be widely used for handling the mixture contained of abrasive and corrosive solids in electric power, metallurgy ,mine, coal, constructional material and chemical industry departments especial for removing ash and sludge in electric power station.

Pump Features:

1. The series ZGB(P) slurry pump is of horizontal, single-stage, single-suction, cantilever, double-casing, centrifugal slurry pump. The pump rotates in clockwise viewed from the drive end.

2. The wet parts of ZGB and ZGBP pump at the same outlet diameter can be interchangeable. Their outline installation dimensions are one and the same. For the drive part of the series ZGB(P) slurry pump, the horizontal split frame with oil lubrication and two sets of water cooling systems inside and outside has been adopted. If necessary, cooling water can be supplied. The prepared joint for cooling water and the pressure of the cooling water can be seen in table 1.

3. Two kinds of shaft seal—expeller seal combined with packing and mechanical seal have been used for series ZGB(P) slurry pump.

4. The mechanical seal supplied with high pressure sealing water is recommended when the slurry pump is operated in series(two stages and above two stages), and the expeller seal combined with packing is used in single-stage pump.

Pump Performance Table:

|

Model |

Speed n(r/min) |

Capacity Q (l/s) |

Head H (m) |

Max.Eff. |

NPSH |

Shaft Power (kw) |

Impeller Dia (mm) |

Pump Weight (kg) |

Outlet /Inlet (mm) |

|

|

65ZGB |

1480 |

31.7-15.8 |

58-61 |

62.5-47.4 |

4.5-3.0 |

28.8-19.9 |

390 |

1850 |

65 / 80 |

|

|

980 |

21.0-10.5 |

25.4-26.7 |

62.5-47.4 |

2.0-1.3 |

8.37-5.8 |

|||||

|

80ZGB |

980 |

56.7-28.3 |

87.5-91.6 |

66.1-48.7 |

5.2-2.7 |

73.7-52.2 |

485 |

2500 |

80 / 100 |

|

|

740 |

37.5-18.8 |

38.4-40.2 |

66.1-48.7 |

2.3-1.2 |

21.4-15.2 |

|||||

|

980 |

52.0-26.0 |

73.7-77.1 |

66.1-48.7 |

4.4-2.3 |

56.8-40.4 |

445 |

||||

|

740 |

34.4-17.2 |

32.3-33.8 |

66.1-48.7 |

1.9-1.0 |

16.5-11.7 |

|||||

|

980 |

46.8-23.3 |

59.5-62.3 |

66.1-48.7 |

3.5-1.8 |

41.3-29.2 |

400 |

||||

|

740 |

31.0-15.4 |

26.1-27.3 |

66.1-48.7 |

1.5-0.8 |

12.0-8.4 |

|||||

|

100ZGB |

1480 |

116.7-58.3 |

85.1-91.8 |

77.9-57.4 |

6.0-2.6 |

124.9-91.4 |

500 |

3000 |

100 / 152 |

|

|

980 |

77.3-38.6 |

37.3-40.3 |

77.9-57.4 |

2.7-1.2 |

36.3-26.6 |

|||||

|

1480 |

105-52.5 |

68.9-78.4 |

77.9-57.4 |

4.9-2.1 |

91.0-66.7 |

450 |

||||

|

980 |

69.5-34.8 |

30.2-32.6 |

77.9-57.4 |

2.1-1.1 |

26.4-19.4 |

|||||

|

1480 |

93.4-46.7 |

54.5-58.8 |

77.9-57.4 |

3.8-1.7 |

64.0-46.9 |

400 |

||||

|

980 |

61.8-30.9 |

23.9-25.8 |

77.9-57.4 |

1.7-0.8 |

18.6-13.6 |

|||||

|

150ZGB |

980 |

200-100 |

85.2-90.0 |

77.7-53.3 |

3.8-2.7 |

215.0-165.5 |

740 |

3450 |

150 / 200 |

|

|

740 |

151.2-75.6 |

48.6-51.3 |

77.7-53.3 |

2.2-1.5 |

92.7-71.3 |

|||||

|

980 |

182.4-91.2 |

73.0-77.1 |

77.7-53.3 |

3.3-2.3 |

168.0-129.3 |

685 |

||||

|

740 |

140.0-70.2 |

41.6-44.0 |

77.7-53.3 |

1.9-1.3 |

74.2-56.8 |

|||||

|

980 |

169.2-84.6 |

61.8-65.2 |

77.7-53.3 |

2.8-1.1 |

131.9-101.5 |

630 |

||||

|

740 |

129.6-64.8 |

35.2-37.2 |

77.7-53.3 |

1.6-0.6 |

57.6-44.3 |

|||||

|

200ZGB |

980 |

300.0-150.0 |

89.0-94.2 |

76.3-63.2 |

6.7-2.7 |

342.9-219.1 |

740 |

4000 |

200 / 250 |

|

|

740 |

226.5-113.3 |

50.7-53.7 |

76.3-63.2 |

3.8-1.5 |

147.5-97.3 |

|||||

|

980 |

283.8-141.9 |

79.6-84.3 |

76.3-63.2 |

6.0-2.4 |

290.2-185.8 |

700 |

||||

|

740 |

214.3-107.1 |

45.4-48.1 |

76.3-63.2 |

3.4-1.4 |

125.0-80.0 |

|||||

|

980 |

259.5-129.7 |

66.6-70.5 |

76.3-63.2 |

5.0-2.0 |

222.0-141.8 |

640 |

||||

|

740 |

195.9-97.9 |

38.0-40.2 |

76.3-63.2 |

2.9-1.1 |

95.6-61.0 |

|||||

|

250ZGB |

980 |

400.0-200.0 |

84.0-90.1 |

78.2-63.2 |

7.3-3.3 |

421.2-275.6 |

740 |

4500 |

250 / 300 |

|

|

740 |

302.0-151.0 |

47.9-51.4 |

78.2-63.2 |

4.2-1.9 |

181.4-118.7 |

|||||

|

980 |

378.4-189.2 |

75.2-80.6 |

78.2-63.2 |

7.1-3.0 |

356.7-233.2 |

700 |

||||

|

740 |

285.7-142.9 |

42.9-46.0 |

78.2-63.2 |

4.0-1.7 |

153.7-100.5 |

|||||

|

980 |

348.6-131.6 |

63.8-68.5 |

78.2-63.2 |

5.5-2.5 |

278.8-137.9 |

645 |

||||

|

740 |

263.2-99.4 |

36.4-39.1 |

78.2-63.2 |

3.1-1.4 |

120.1-59.4 |

|||||

|

300ZGB |

980 |

533.3-266.7 |

84.3-93.4 |

81.2-68.3 |

6.9-3.5 |

542.8-357.6 |

760 |

5500 |

300 / 350 |

|

|

740 |

402.7-201.3 |

48.1-53.3 |

81.2-68.3 |

3.9-2.0 |

233.9-154.0 |

|||||

|

980 |

493.3-246.7 |

72.1-79.9 |

81.2-68.3 |

5.9-3.0 |

429.4-282.9 |

703 |

||||

|

740 |

372.5-177.9 |

41.1-45.6 |

81.2-68.3 |

3.4-1.7 |

184.8-116.4 |

|||||

|

980 |

453.3-226.7 |

60.9-67.5 |

81.2-68.3 |

5.0-2.5 |

333.3-219.7 |

646 |

||||

|

740 |

342.3-171.2 |

34.5-38.5 |

81.2-68.3 |

2.9-1.4 |

143.4-94.6 |