TZPC/CH High Head Microtunneling Feed Slurry Pump

Description

TZPC/CH Slurry Pumps are designed for corrosive and light abrasive duties, handling dirty water or low concentration slurries. they are particularly suited to light slurry duties requiring greater reliability and durability than conventional process pumps.

The TZPC Pump range features an unlined casing design, characterised by design simplicity,minimum number of parts, and light overall weight. However, to avoid loss of lubrication to the oil lubricated bearings, it is recommended that these pumps only be operated with the pump axis horizontal. They have a high discharge pressure, with maximum head up to 125 m per stage. High operating efficiency is maintained over the life of casing wear parts, resulting in low energy costs.

The pumps may be fitted with a range of seal types depending on the particular requirements.Standard seal options comprise the BODA centrifugal seal, with grease lubricated packed gland, and a water flushed packed gland seal. Third party mechanical seals may also be fitted where special sealing requirements favour this type of seal.

Bearings are provided with oil bath lubrication. In view of this it is essential that the pumps be operated only with the shaft horizontal to avoid loss of lubrication to one bearing that would otherwise occur.

The BODA TZPC/CH Pump is designed for back pull-out dismantling of the Frame and Shaft assembly from the Casing, which remains in place, connected to the intake and discharge pipework. This enables a rapid replacement of Frame and Shaft assembly with a standby unit, while leaving the pipework undisturbed.

Feature of the Pump

This series is a high-head centrifugal slurry pump specially designed by us. Its head performance is increased by up to 50% compared with conventional slurry pumps. It has a compact structure and small volume, and can still operate efficiently in limited spaces. The key flow-through components of this series of pumps are made of wear-resistant and corrosion-resistant materials such as high-chromium alloy and duplex stainless steel, which can handle highly abrasive media, significantly extend the service life, and reduce maintenance and spare parts costs. Its impeller side blade design effectively reduces seal wear, the clamp-type structure enables quick disassembly and assembly, the centrifugal seal does not require external shaft seal water, and combined with the heavy-duty bearing system, it ensures high reliability and operating efficiency in harsh working conditions.

Identification Of Parts

Each Boda pump part has a unique name and a three-digit Basic Part Number. Parts with the same name have the same Basic Part Number, regardless of pump size. For example, the Expeller of every Boda pump has the Basic Part Number 028.Additional letters and numbers are added before and after the Basic Part Number to further define a component part of a particular pump, as described in Part 1 of the Assembly,Operating, and Maintenance Instruction Manual. This expanded marking is identified as the Part Number, and represents a unique identification for each component part. The Part Number is normally cast or otherwise prominently marked on each part. For example, Part Number PD10222 identifies the Casing to fit the 100 TZPD-PC Boda Pump.Refer to the Component Diagram of the appropriate size of Boda Pump for complete identification and description of component parts. Part names and Basic Part Numbers are used in assembly instructions throughout this instruction manual. Boda Basic Part Numbers for all component parts of Type ‘TZPC’ pumps are listed in the Appendix of this publication.In all communications with Boda Industrial Pump and particularly when ordering spare parts, it is recommended that the correct component names and Part Numbers be used at all times to avoid supply of incorrect part

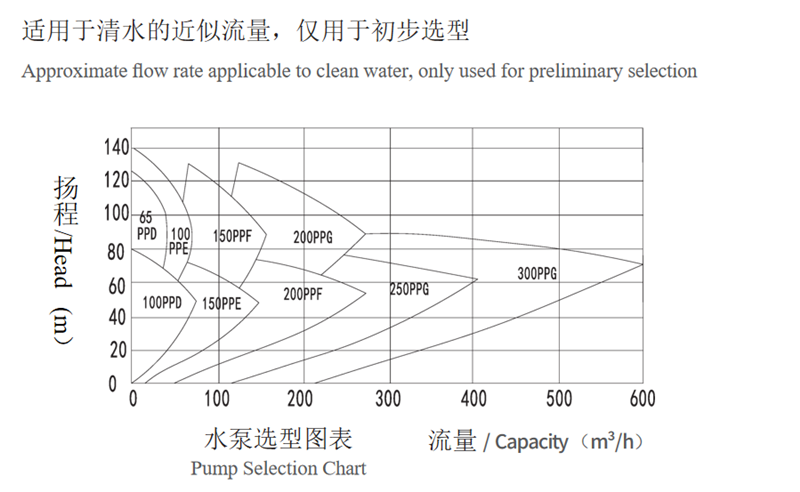

Approximate flow rate applicable to clean water, only used for preliminary selection