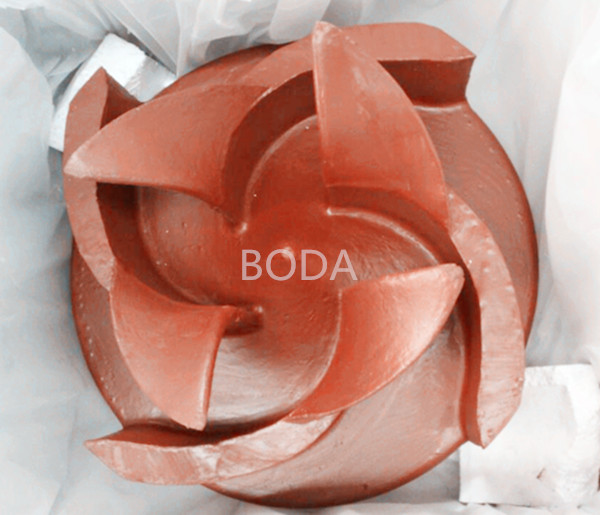

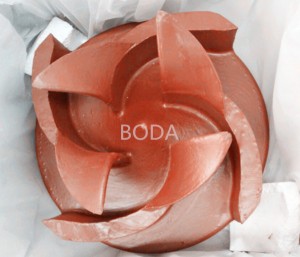

Abrasive slurry pump parts Slurry Pump Impeller

Slurry pump impeller can play an extremely important role in the operation of slurry pump.By rotating, it can help slurry pump meet the needs of the equipment.One issue we concern is that our product is easy to worn out, so we search for the special materials to prolong the lifespan of impeller.Later on, we found two types of materials accord with the requirement of our slurry pump impeller, including the natural rubber as well as the white iron with high chrome content of 27%.The natural rubber is to deal with the corrosive slurries with blunt particles.Meanwhile,the white iron with high chrome aims at handling slurries with strong abrasion or sharp particles.

As a China-based slurry pump impeller manufacturer, we provide a broad range of products, including forth pump, medium/light duty slurry pump, sump pump and FGD flue gas desulfurization pump among others.

OEM part codes

Here we list some OEM part codes for reference:

Impeller: 127, 147, 145, etc., such as BDC2127, BDD3147, BDE4147, BDF6147, BDG8147, BDG10147, BDFAM1247...

Slurry Pump Main parts:

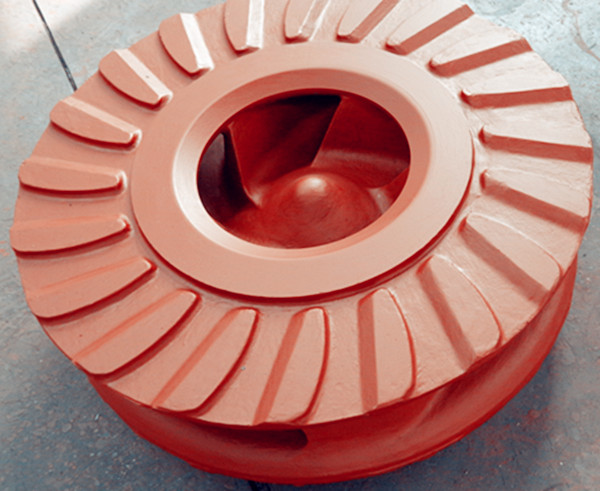

• Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.

Hard metal and molded rubber impellers are complete interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

• Liners - Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer

seal rings back all liner joints.

• Throat Bush - Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

• Bearing assembly - A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

Slurry Pump Spare Parts

Slurry pump wet end parts mainly include Impeller, volute liner, Casing, shaft, throat bush, wear plate, case, cover, stuffing box, lantern restrictor, cover plate bolt, throat bush, shaft sleeve, cover plate liner, frame plate liner...

1.centrifugal slurry pumps and spare parts can fully interchange with world famous brand.

2.These pumps are of heavy-duty construction, designed for continuous pumping of highly abrasive and corrosive slurries.

3. They feature a wide choice of replaceable abrasion resistant metal or moulded elastomer elastomer elastomer casting liners and Impellers, which are all interchangeable within a common casting assembly.

4.Wear -resistant Metal Liner and Rubber Liner available

5.Seal Type: gland seal , impeller seal and mechanical seal

6.Can be installed in multistage series

7.easy to maintenance

The properties of the rubber material:

We have variety of natural rubber and elastomers, which can be used for pumping corrosive or acid slurries. But the rubber material is not suitable for slurries which contain sharp solids.When the slurries contain fine particles, the rubber material features good performance of wear resistant.

The properties of the high chrome white iron:

We have variety of high chrome white iron, and the content of chrome is different.

They can offer excellent performance under erosive conditions. The alloy can be effectively used in a wide range of slurry types. The high wear resistance of alloy is provided by the presence of hard carbides within its microstructure. Some special high chrome alloy is also suited to application where corrosion resistance, as well as erosion resistance is required.

OEM Service

Based on many years of rich experience in slurry pump manufacturing and design, BODA can undertake OEM customization for the whole set of pump and various spare parts. The slurry pump spare parts can be made of various material according to customer's requirement, Such as: Alloy 20, Hastelloy Alloy, A (6 1 ) and so on.

Our company undertakes the design, processing and transformation of various special pump parts. According to the user's requirements, BODA Factory can manufacture various materials and components to meet the needs of different working conditions. Or in accordance with user requirements on the existing equipment technology transformation, combined with our company's rich hydraulic model, through advanced computer simulation technology, to provide users with a complete and effective solution.

Application:

The parts are widely used in Main Applications: Heavy Mining Mineral Processing Sand and Gravel Coal Prep Cyclone Feeds Aggregate Processing Fine Primary Mill Grinding Chemical Slurry Service Tailings Secondary Grinding Industrial Processing Pulp And Paper Food Processing Cracking Operations Ash Handling Pipeline Transport High Velocity Hydraulic Transport Food Processing Explosive Sludge In Metal Smelting River And Pond Dredging Heavy Refuse Removal Larger Particle Or Low NPSHA Applications Continuous (Snore) Sump Pump Operation Abrasive Slurries High Density Slurries Large Particle Slurries Sump Drainage Wash down Floor Drainage Mixing Iron Ore Cooper Diamond Alumina Coal Gold Kaolin Phosphorite Steel Palm Suger Chemical Power FGD Frac Sand Blending Construction City Sewage etc.