BTL/BDTL Series Slurry Circulation Pump

Nkọwa ngwaahịa:

1) Akụkụ ndị na-egbochi mgbapụta na-enweta teknụzụ ịme anwansị dị elu iji kwe nkwa ntụkwasị obiimewe mgbapụta na arụmọrụ dị elu na-arụ ọrụ.

2) The anticorrosion & antiwear metal na roba ihe nke emepụtara kpọmkwem maka FGDegosipụtara nfuli site na omume na, ha nwere ike hụ na ọrụ mgbapụta ogologo ndụ.Site n'ịgbanwe ihe ndị na-ebu ibu iji gbanwee ọnọdụ impeller na ụlọ mgbapụtaEnwere ike ịrụ ọrụ dị elu nke oge niile nke mgbapụta ahụ.A na-eji mgbapụta mara azụ azụusoro ịkụ aka nke dị mfe ma dị elu.

3) Ọ dị mfe ịnọgide na-arụzi ma na-arụkwa ya na ọ dị mkpa ịkwatu mmiri ntinye na ntinye mmiri.The containerized n'ibu akara pụrụ iche eji maka desulphurization usoro na-nakweere naa pụrụ ịdabere na ya ọrụ.

Nhọrọ ihe:

anyị azụlitela ọhụrụ ụdị pụrụ iche ihe onwunwe nke nwere duplex igwe anaghị agba nchara anti-corrosive onwunwe na elu chrome ọcha ígwè mgbochi abrasive onwunwe na FGD usoro.

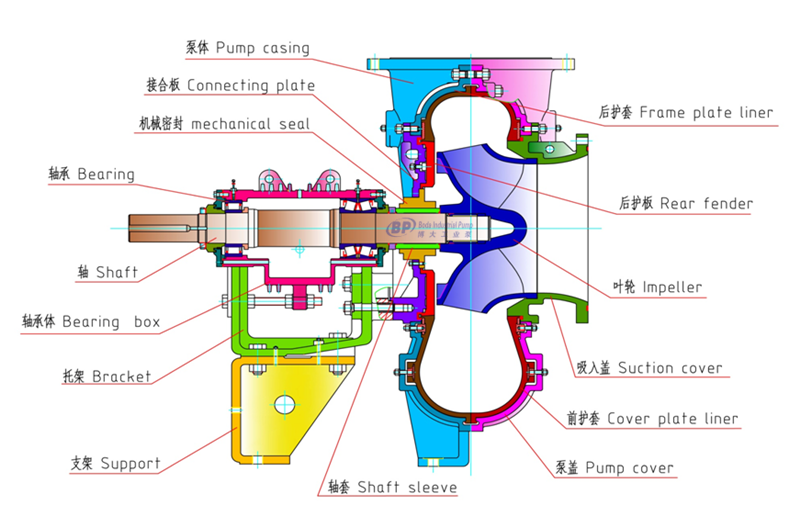

Na roba mgbapụta casing, impeller, suction cover / cover efere na-niile mere nke pụrụ iche mgbochi eyi na mgbochi corrosive ihe: ihe nke n'ihu liner, azụ liner na azụ liner ntinye bụ eke roba nwere magburu onwe mgbochi corrosive onwunwe.

Na metal mgbapụta casing, impeller, volute liner, suction efere na azụ efere na-niile mere nke pụrụ iche mgbochi eyi na mgbochi corrosive ihe, mmiri cover na-mere nke ductile ígwè na roba.

Njirimara ihe owuwu:

1) A na-emepụta akụkụ mgbapụta mgbapụta site na CFD Flow Simulating Analysis Techniques dị elu iji hụ na atụmatụ ya nwere ntụkwasị obi na arụmọrụ ya.

2) Ọ nwere ike ịgbanwe ọnọdụ nke impeller na mgbapụta mgbapụta site n'ịgbanwe mgbakọ na-ebu ibu iji mee ka mgbapụta ahụ na-arụ ọrụ dị elu mgbe niile.

3) Ụdị mgbapụta a na-eme ka usoro mmepụta azụ azụ, na-edebe ihe owuwu ya dị mfe na nhazi dị mfe.Ọ dịghị mkpa igbasa ụzọ mbata na ọpụpụ pipeline.

4) A na-edozi ihe nkedo abụọ nke taper roller na njedebe nke mgbapụta ahụ, a na-edozi ihe mkpuchi nke kọlụm na njedebe ịkwọ ụgbọala. A na-eji mmanụ lubricated na-ebu mmanụ. Ihe ndị a niile nwere ike imeziwanye ọnọdụ ọrụ na-arụ ọrụ ma mee ka ndụ ya dịkwuo mma.

5) Mechanical akara na adpoted integrating n'ibu akara nke bụ pụrụ iche na FGD technology iji hụ na ya ọrụ.

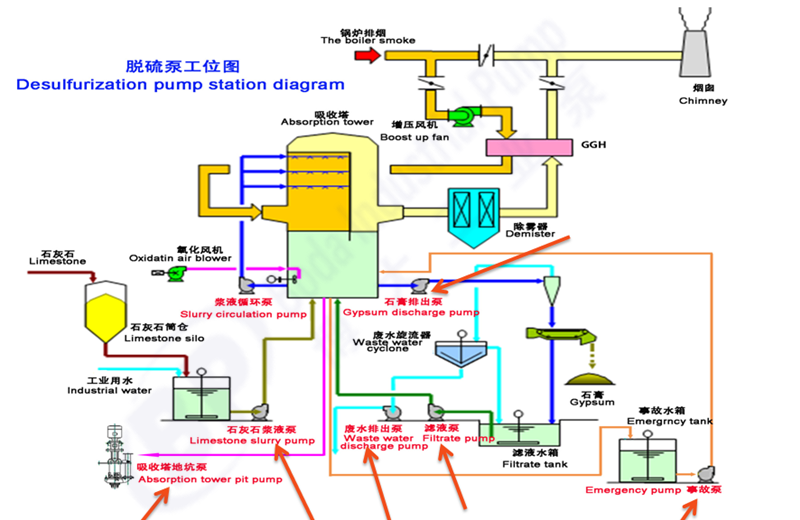

Ngwa:

A na-ejikarị ha eme ihe iji na-edozi slurry na anwụrụ ọkụ n'ụlọ elu absorption nke ọdụ ọkụ eletrik,Nke ahụ bụ ụlọ ọrụ ọkụ ọkụ FGD (Flue Gas Desulfurization) Project.

Ọdịdị mgbapụta:

Chaatị Nhọrọ:

Data nka nka:

| Nlereanya | Ike Q(m3/h) | Isi H(m) | Ọsọ (r/min) | ff. (%) | NPSHr (m) |

| BDTL400 | 1800-2800-3400 | 13-28-35 | 400-740 | 78-82 | 5 |

| BDTL450 | 2900-3600-4500 | 15-25-35 | 480-740 | 80-84 | 5 |

| BDTL500 | 3400-4250-5400 | 16-28-32 | 350-590 | 80-85 | 5.2 |

| BDTL600 | 4000-5300-6300 | 15-25-28 | 350-590 | 83-87 | 5.6 |

| BDTL700 | 6000-7200-9000 | 15-25-30 | 425-590 | 83-87 | 6 |

| BDTL800 | 7450-10000-12000 | 15-24-30 | 425-590 | 83-87 | 7 |

| BDTL900 | 8400-12000-15000 | 12-21-25 | 400-460 | 84-89 | 7.2 |

| BDTL1000 | 9800-14000-18000 | 15-23-25 | 360-400 | 83-87 | 7.0 |