BTL/BDTL Series Slurry Circulation Pump

Hōʻike huahana:

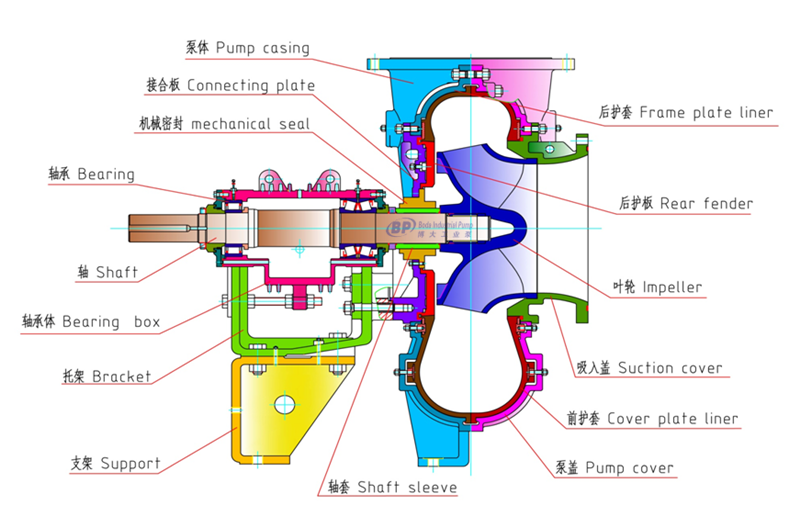

1) Hoʻohana nā ʻāpana hoʻopaʻa ʻana i ka ʻenehana simulation holomua e hōʻoia i ka hilinaʻika hoʻolālā pump a me ka hana kiʻekiʻe.

2) ʻO nā mea metala anticorrosion & antiwear a me nā mea hao i hoʻomohala ʻia no FGDua hōʻoia ʻia nā pumps e ka hoʻomaʻamaʻa ʻana, hiki iā lākou ke hōʻoia i ka hana lōʻihi o ka pauma.Ma o ka hoʻoponopono ʻana i nā ʻāpana bearing e hoʻololi i ke kūlana impeller ma ke keʻena pamuhiki ke hoʻokō i ka hana kiʻekiʻe o ka pauma.Hōʻike ʻia ka pamu e ke kuahale kuʻikuʻi i maʻalahi a holomua.

3) He maʻalahi ka mālama ʻana a me ka hoʻoponopono ʻana a pono ia e wehe i nā paipu wai inlet a me waho.Hoʻohana kūikawā ʻia ka pahu pahu mechanical sila no ke kaʻina desulphurization ahilinaʻi kāna hana.

Koho Material:

ua hoʻomohala mākou i kahi ʻano mea kūikawā hou nona ka waiwai anti-corrosive duplex stainless steel a me ka waiwai anti-abrasive o ka hao chrome keʻokeʻo kiʻekiʻe i ka hana FGD.

I loko o ka pahu pahu pahu, impeller, suction cover/cover plate i hana ʻia me nā mea anti-wear specialized a me nā mea anti-corrosive: ʻo ka mea o ka liner mua, ka laina hope a me ka hoʻokomo ʻana i hope he ʻupena maoli nona ka waiwai anti-corrosive maikaʻi loa.

I loko o ka pahu metala pump casing, impeller, volute liner, suction plate a me back plate i hana ʻia me nā mea anti-wear kūikawā a me nā mea anti-corrosive, ua hana ʻia ka uhi hoʻoheheʻe i ka hao ductile me ka lāʻau.

Hiʻona Hana:

1) Hoʻolālā ʻia nā ʻāpana kahe wai e nā CFD Flowing Simulating Analysis Techniques e hōʻoia i ka hilinaʻi o kāna hoʻolālā a me kāna hana pono.

2) Hiki iā ia ke hoʻololi i ke kūlana o ka impeller i ka pahu pahu ma ka hoʻoponopono ʻana i ka hui lawe ʻana e mālama i ka hana kiʻekiʻe o ka pauma i nā manawa āpau.

3) Hoʻohana ʻia kēia ʻano pamu i ka hoʻihoʻi ʻana i waho, e mālama ana i kāna hana maʻalahi a mālama maʻalahi.ʻAʻole pono ia e wehe i ka pipeline inlet & outlet.

4) Hoʻopaʻa ʻia ʻelua mau ʻāpana o ka taper roller bearings i ka hopena o ka paila, ua hoʻolako ʻia ke kolamu roller bearing ma ka hopena hoʻokele.

5) Hoʻopili ʻia ka sila mīkini e hoʻohui i ka sealing mechanical i loea i ka ʻenehana FGD e hōʻoia i kāna hana.

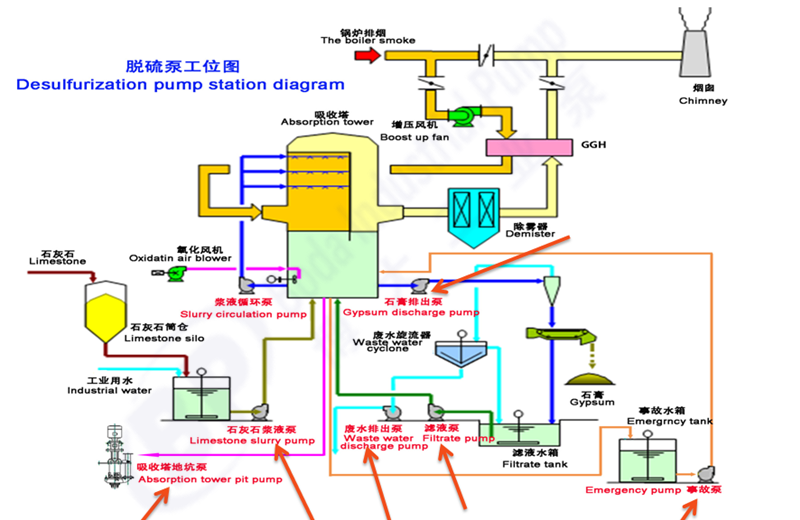

Nā noi:

Hoʻohana nui ʻia lākou e mālama i ka slurry me ka uahi i ka hale kiaʻi absorption o ka mana uila,ʻo ia ka papahana FGD (Flue Gas Desulfurization).

Hoʻokumu ʻia ʻo Pum:

Papa koho:

ʻIkepili ʻenehana:

| Hoʻohālike | Ka hiki Q(m3/h) | Poʻo H(m) | Ka māmā holo (r/min) | eff. (%) | NPSHr (m) |

| BDTL400 | 1800-2800-3400 | 13-28-35 | 400-740 | 78-82 | 5 |

| BDTL450 | 2900-3600-4500 | 15-25-35 | 480-740 | 80-84 | 5 |

| BDTL500 | 3400-4250-5400 | 16-28-32 | 350-590 | 80-85 | 5.2 |

| BDTL600 | 4000-5300-6300 | 15-25-28 | 350-590 | 83-87 | 5.6 |

| BDTL700 | 6000-7200-9000 | 15-25-30 | 425-590 | 83-87 | 6 |

| BDTL800 | 7450-10000-12000 | 15-24-30 | 425-590 | 83-87 | 7 |

| BDTL900 | 8400-12000-15000 | 12-21-25 | 400-460 | 84-89 | 7.2 |

| BDTL1000 | 9800-14000-18000 | 15-23-25 | 360-400 | 83-87 | 7.0 |